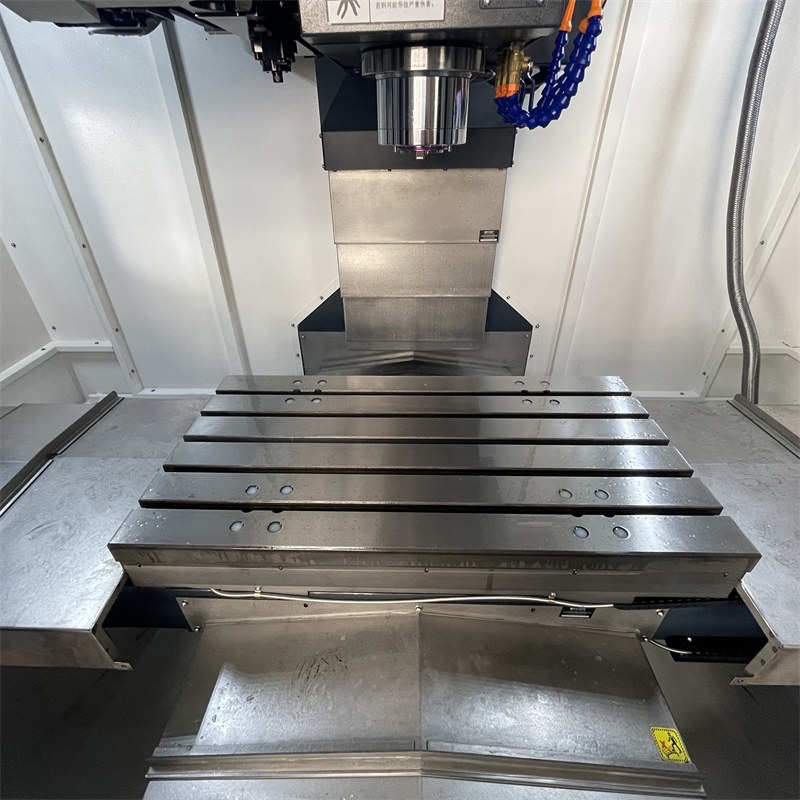

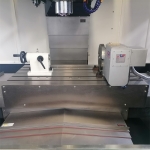

Vertical Machining Center

Whether you need a standard 3-axis mill, a powerful 5-axis vertical machining center, or a small VMC for precision parts, there’s a LETIPTOP to do the work. Find the best machine that meets your workpiece and machining requirements by here.

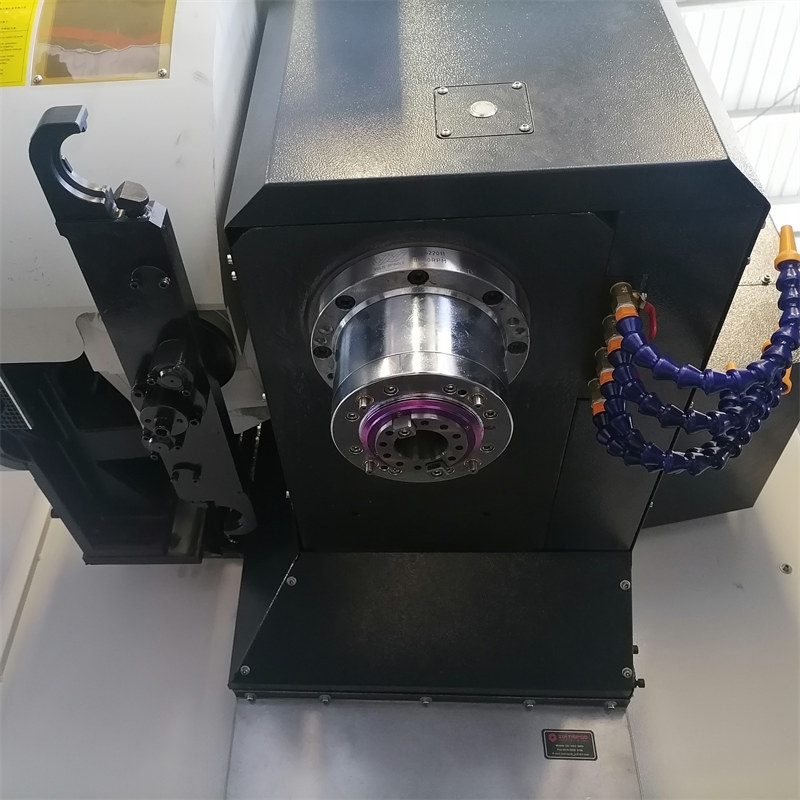

● Spindles: 8,000r/min and 10,000r/min

● Spindle Connections: BT40 and BT50

● ATC: 12, 14 and 24 tools

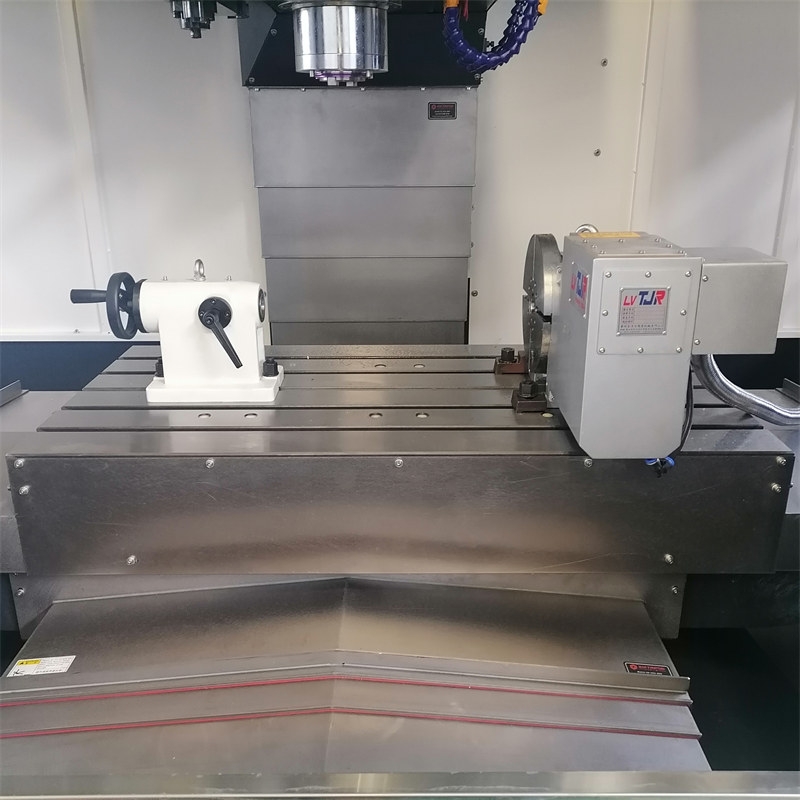

● Series Range: 3-Axis, 5-Axis

Description

The spindle axis of the Vertical Machining Venter is perpendicular to the working table, it can use for milling, boring, drilling, tapping and threads cutting. After clamp the workpiece once on it, the CNC control system can control tools selecting and changing, spindle speed, feeding and tool movement track automatically according to different processes, which can complete multi-process machining on several sides of the workpiece in sequence. It can improve the production efficiency greatly. It mainly used for processing complex parts such as plates, discs, molds and small shells.

● Machine body and main casting parts are made by high intension and high quality cast iron.

● High rigidity, high, reliability and high cutting power.

● A-shape high intension and high rigidity column.

● 3-linear guideway.

● Taiwan 24 position tool storage.

● Taiwan main spindle.

● Feed axis links directly with precision rolling -ball screw drive by servo motor and high precision no spaces coupling.

● Spindle units drive by spindle motor and timing belt.

● Lower noise, smaller libration and lower heating power.

● Lubrication system for bedway, ball screw.

● Optional the fourth axis CNC rotary working table and CNC dividing head.

● Domestic or import CNC control system is available for your selection.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the Vertical Machining Center and talk to LETIPTOP expert.

Technical Parameters

.jpg)

Standard and Optional

.jpg)