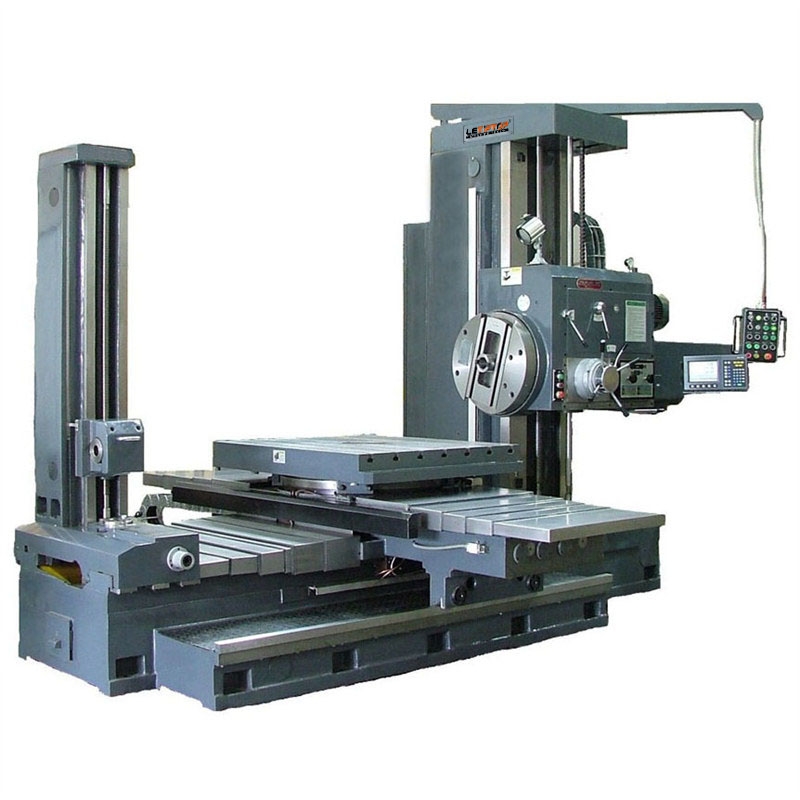

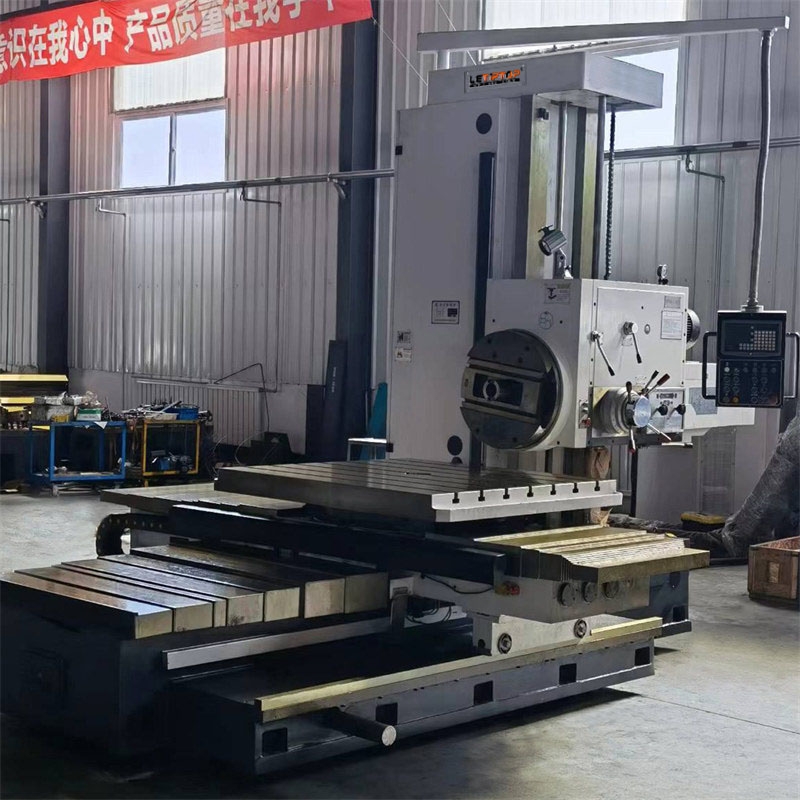

Horizontal Boring Machine

LETIPTOP Horizontal Boring Machine is holding heavy, irregular and off-balance workpiece boring, reaming, turning, threading, facing, milling, grooving, recessing and many other operations with suitable tools.

● Working Table size upto 1600x1400mm

● Working Table size upto 1600x1400mm

● Spindle bore 85-130mm

● Workpiece Loading 1500-8000Kg

● Boring Hole Precision IT7

Description

LETIPTOP Horizontal Boring Machine enables operators to drill holes that exist within a workpiece, enlarging them, improving their dimensional accuracy, or increasing the diameter of the hole in cast, forged workpiece. These processes can also increase surface smoothness and ensure the original hole axis‘s deviation is correct.

● Casting machine base

● Precision hardened and ground bedways

● Centralized automatic lubrication

● X, Y, & Z axes driven by AC motor

● Precision ground ballscrews

● Rapid traverse in all feed directions

● Full steel telescoping way covers on X & W axis

● Air power drawbar

● Three axis electronic DRO

● Compact pendant operation panel

● Hydraulic Clamping

● Coolant system

● The spindle rotation and the feed moving of the machine are all controlled by the hydraulic pre-selection, and the operation is simple and convenient. During the speed change, the indicator lights on the button plane can send out signals.

● The distribution of each moving parts of the machine and the clamping and loosening of the moving parts are all used hydraulic automatic interlocking which has high automation.

● The coordinates of the vertical movement of the headstock and the transverse movement of the worktable all have numerical display function, which improves the machining accuracy of the parts. The vertical coordinate display function of the worktable can also be provided according to the special requirements of users.

● The main guides of the horizontal milling and boring machine such as the bed, the A-post, the saddle, all use the electric contact surface heating and self cooling quenching, which can make the guide rail have a high hardness and prolongs the service life.

● The horizontal guides of the machine are all protected by pull plate type.

● There are electrical and liquid interlocking relations between the moving parts of the machine. When the machine is working, only one moving motion is allowed, and the other parts are clamped automatically (except the spindle and the slide on the facing head).

● The insurance combinations are arranged in the feed box and the quick box, which to make the machine safe when the machine is overloaded.

● The programmable logic controller is adopted in the electrical control of the machine, so the machine’s performance is very reliable.

Technical Parameters

.jpg)

Standard and Optional

.jpg)