China LETIPTOP Gear Hobbing Machine

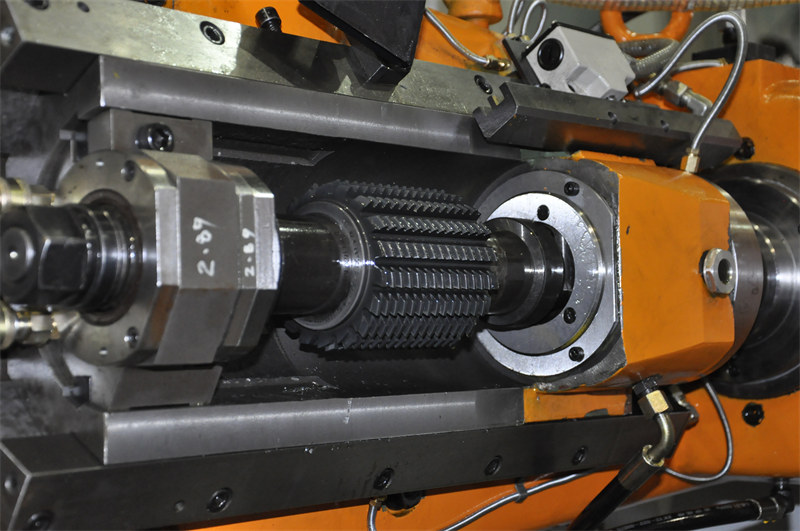

China LETIPTOP Gear Hobbing Machine is a type of machine tool used to produce gears. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a special tool called a hob. The hob is typically a cylindrical tool with helical cutting teeth that progressively cut into the workpiece as it rotates.

In the gear hobbing machine, the workpiece is mounted vertically on a rotary table that can be indexed to move the workpiece into position for cutting. The hob is mounted on a vertical spindle that can be adjusted to vary the height of the hob relative to the workpiece. As the workpiece rotates, the hob is fed into the workpiece, cutting teeth into the gear as it rotates.

China LETIPTOP Gear Hobbing Machines are typically used to produce gears with a large diameter or a large number of teeth. They are often used in the production of gears for heavy machinery such as industrial equipment, wind turbines, and marine propulsion systems. These machines are capable of producing high-precision gears with excellent surface finish and can be programmed to produce a wide range of gear types and sizes.

Working Principle: The gear hobbing machine works on the principle of generating gears. The hobbing tool (hob cutter) is a cutting tool that has helical teeth that are arranged in a spiral around the circumference of the tool. The hob is fed into the workpiece while the workpiece is rotated, resulting in the hob cutting the teeth into the workpiece.

Vertical configuration: The vertical configuration of the machine allows for the workpiece to be mounted vertically on a rotary table, making it suitable for producing gears with a large diameter. The hob is mounted on a vertical spindle, which can be adjusted to vary the height of the hob relative to the workpiece.

Cutting Parameters: The cutting parameters, such as hob speed, feed rate, and depth of cut, are critical to achieving the desired gear specifications. These parameters can be adjusted to produce gears of different sizes, types, and materials.

Accuracy: Gear hobbing machines are capable of producing gears with a high degree of accuracy and precision. The machines are equipped with features like electronic hob shifting and automatic tool setting, which ensure consistent gear quality and minimize human error.

Applications: Gear hobbing machines are widely used in the manufacturing of gears for various industries, including automotive, aerospace, construction, and marine. They are ideal for producing large gears used in heavy machinery, such as turbines, mining equipment, and cranes.

Maintenance: Maintenance is critical to ensure the longevity and optimal performance of the machine. Regular lubrication and cleaning of the machine components are necessary to prevent wear and tear and ensure smooth operation. The cutting tool (hob) must also be regularly inspected and replaced when worn out.

If you have any interest, welcome to contact us via email sales@tiptopmfg.com for a formal quote and talk to LETIPTOP expert to get the support. For more information, please click China LETIPTOP Gear Hobbing Machine to view.