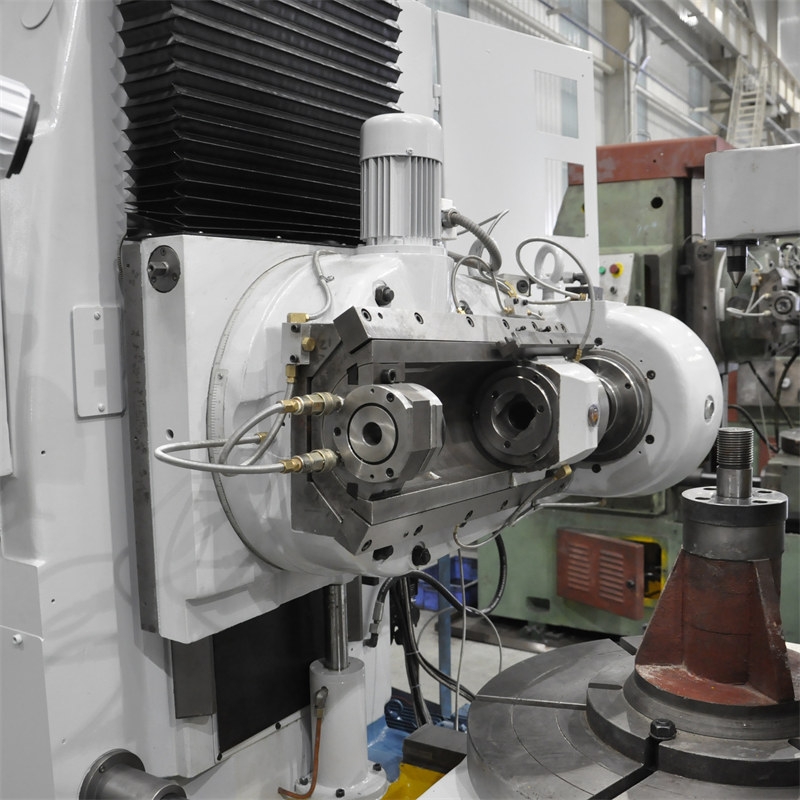

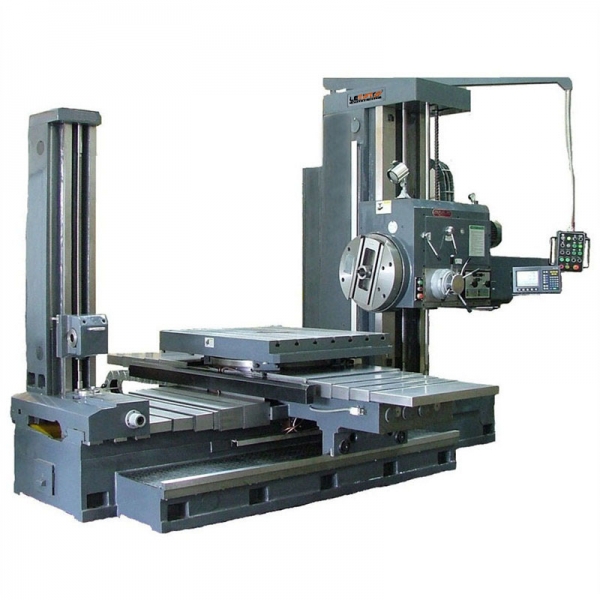

Gear Hobbing Machine

Gears play a very important role in the industry. LETIPTOP Gear Hobbing Machine is specially used for production of spur gears, helical gears, worm gears and sprockets. It is really an idea machine suitable for in the machining workshop, maintenance workshop and tool production workshop.

● Spur gear, helical gear, worm gear and sprocket hobbing

● Spur gear, helical gear, worm gear and sprocket hobbing

● Gear hobbing module range from 5mm to 40mm

● Gear hobbing diameter upto grade 12.5m

● Gear hobbing accuracy upto grade 6.

● NC and CNC for your choice.

Description

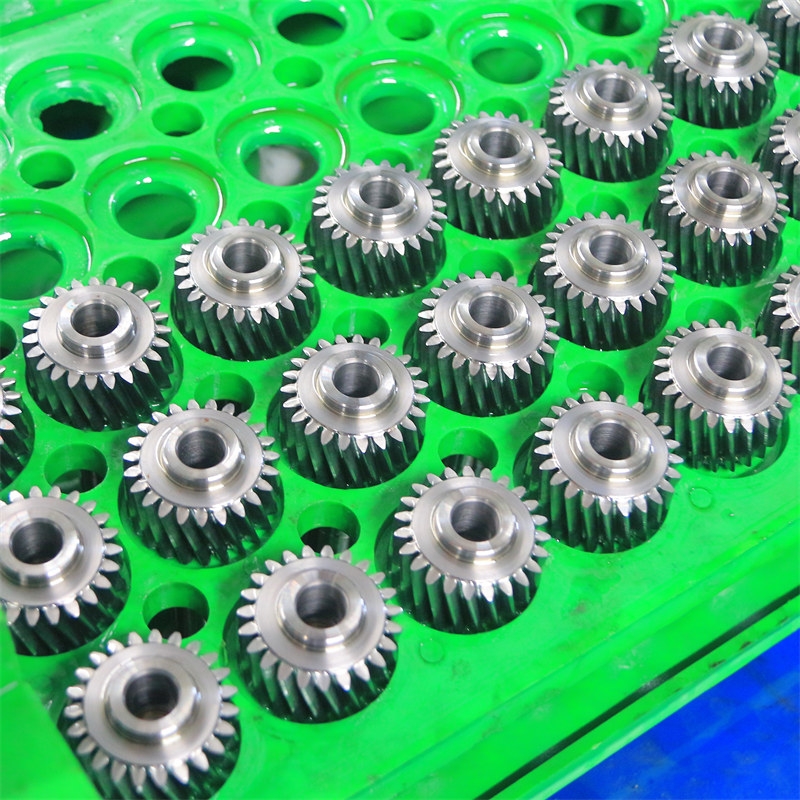

Gear Hobbing Machine is used in gear processing workpshop. It can cut spur gear, helical gear, worm gear and sprocket wheel. It can also process various workpiece with special tooth-shape such as spline gear and sprocket with the special hob cutter. The machining accuracy of the regular gear hobbing machine is grade 7 to 6 (JB179-83), and the high precision gear hobbing machine is grade 4 to 3. The maximum processing gear diameter upto 12.5 meters. It is widely used in various machinery manufacturing industries such as automobile, tractor, machine tools, construction machinery, mining machinery, metallurgical machinery, petroleum, instrumentation, and aircraft spacecraft and so on.

● The shafts & Gears are made of alloy steels.

● spur gear, helical gear, worm gear, sprocket wheel, spline gear can be hobbed.

● Raised height of vertical column and stroke effectively expand the working range.

● Mechanism with electric tool leap allows longer hob and greatly increases service life of the cutting tool.

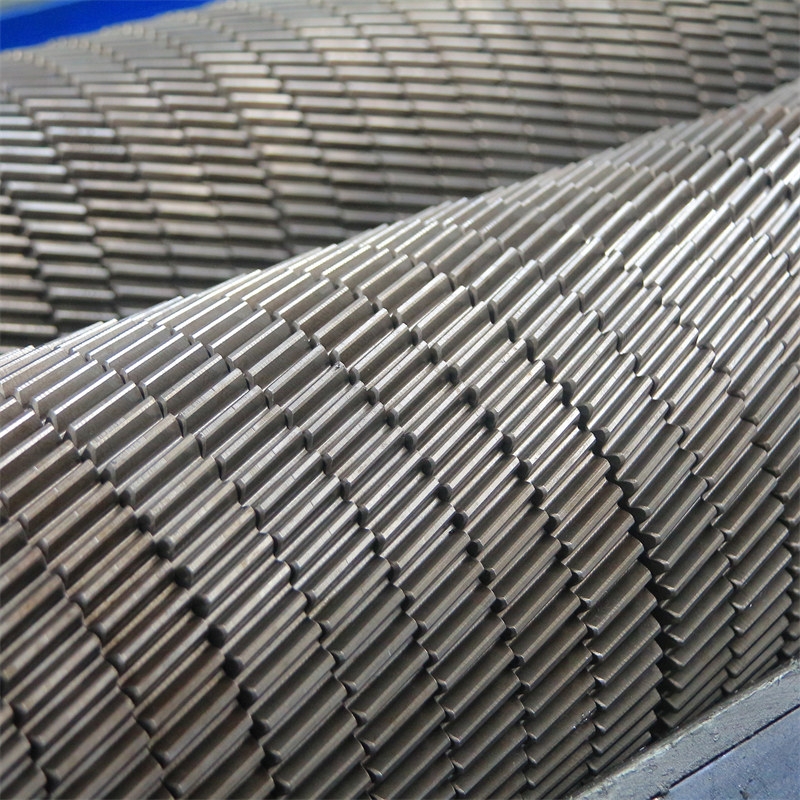

● Worm gear of a high precision over five grade features long service ife and steady accuracy.

● Traditional bearings along the hobs are replaced with rolling bearings to enable greater speed of the tools.

● External support of the small column tailstock adopts the hinge structure and can be easily opened outward, convenient to hang components of large diameters.

● Oil reservoirs are provided in the machine which ensures thorough lubrication of Gears & Bearings.

● It can process gear with down milling and up milling method in axial or radial way.

● CNC controller is available for processing crown gear and small taper gear.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the Gear Hobbing Machine and talk to LETIPTOP expert.

Technical Parameters

.jpg)

Standard and Optional

.jpg)